Why

Choose Us?

PAEL provides Exchangers Cleaning services with advance HP Jetting Machines under pressure range of 5000 psi ~ 30,000 psi.

PAEL provides Exchangers Cleaning services with advance HP Jetting Machines under pressure range of 5000 psi ~ 30,000 psi.

Pak Arab Is Serving his Cleaning Services (High pressure water jetting) in national industries to clean Heat exchangers, Vessels, Columns, Tanks, Fin Fan coolers.

PAEL provides Exchangers Cleaning services with advance HP Jetting Machines under pressure range of 5000 psi ~ 30,000 psi.

With our immense industrial experience, we are engaged in offering a wide range of High-Pressure Water Jetting Services. Having developed in various sizes, designs and models, our offered equipment is highly used for various blasting applications such as rust & scale removal and coating & contaminant removal. High pressure water jetting is a cost-effective and environmentally friendly alternative to using aggressive chemicals and solvents to remove contamination.

“PakArab Engineering Limited high-pressure water jetting is a very effective way of not only removing deposits & coatings from tanks, vessels and pipe work. Cleaning of reactors, vessels and tanks has to be completed to a very high standard in order to ensure efficient production and prevent product cross-contamination and / or contamination by cleaning products. By thoroughly cleaning vessels with water alone, the jetting systems approach ensures product quality and is more cost efficient, improving productivity without having to worry about disposal of cleaning chemicals.

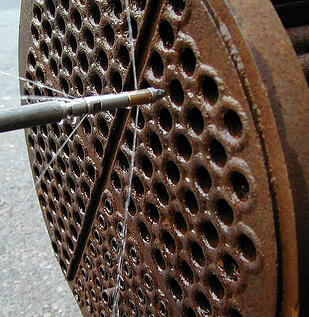

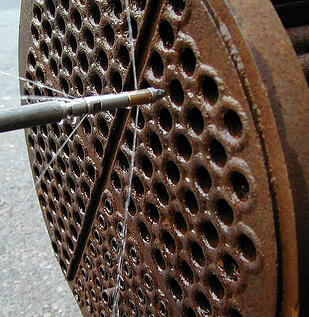

Pak Arab Engineering Limited uses the Specialized “FLEX LANCING’’ Technique for Tube Opening & Cleaning. Using Water at High Pressure as a “Scale Removal source” this is the most durable and effective method of Tube Cleaning. This is an environment friendly method having no adverse effect of Metallurgy of the Equipment to be cleaned.

Water Lancing is an environmentally-safe method used to handle cleaning and Tubes Internal choking problems in a variety of industrial applications. This versatile technology has been proven effective for use with materials as diverse as rubber, composites, metals and even foodstuffs.

Water Lancing is environment friendly in that it does not produce hazardous water products often found in the manufacturing process. In addition, Water Lancing uses small amounts of water, which can be recycled using a closed loop system. Water jetting also reduces the release of fumes and contaminants from materials such as fiberglass and asbestos, thereby creating a safer environment for equipment operators. By utilizing this method all kinds of Tubes can be DE choked, both straight and U type. This Technique Effectively Cleans:

PakArab Engineering uses the Specialized “FLEX LANCING’’ Technique for Tube Opening & Cleaning. Using Water at High Pressure as a “Scale Removal source” this is the most durable and effective method of Tube Cleaning. This is an environment friendly method having no adverse effect of Metallurgy of the Equipment to be cleaned.